Who We Are?

SINCE 1968, WITH A PASSION FOR ABUNDANCE…

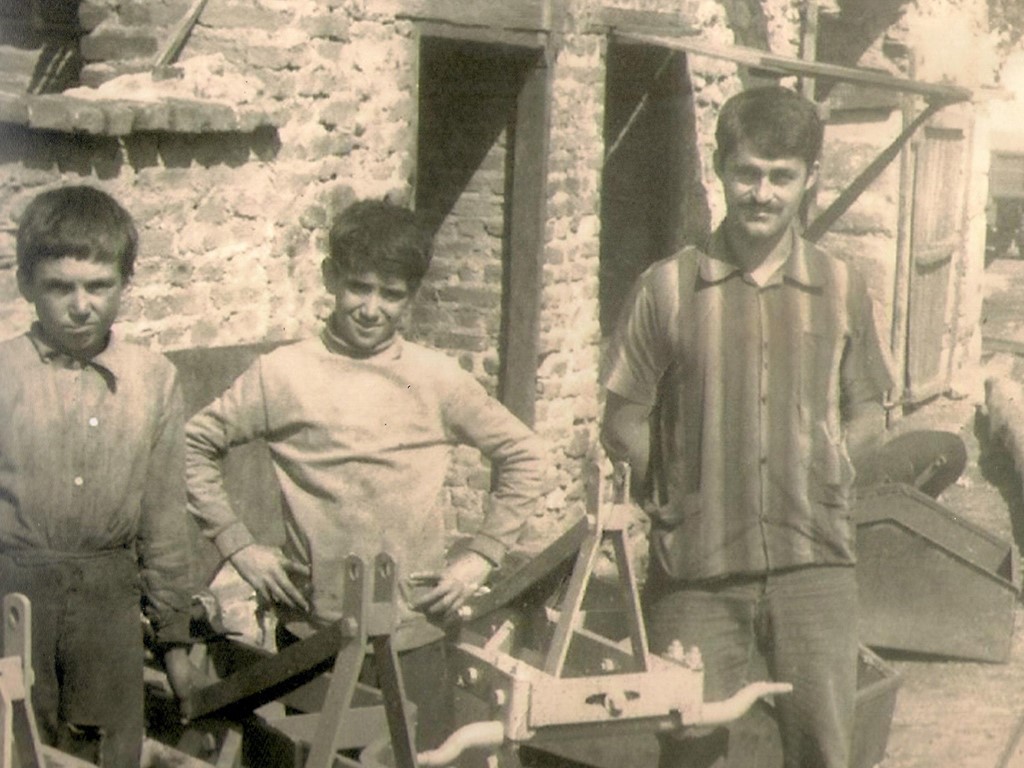

Nihat Koç, born into a Yörük family in 1946 in Arapkuyusu Village, Aydın, began his journey in a family deeply rooted in traditional trades. As one of Ali Koç’s seven children, who worked in transportation with camels, Nihat completed his primary education in his village. following primary school, he enrolled in Aydın High School but left after the second year of middle school to apprentice with a blacksmith.

In the blacksmith’s workshop, where agricultural machinery repairs and plough work were conducted, the young and strong Nihat Koç mastered the art of forging and became a skilled blacksmith. After working in the workshop for seven years, he served in the military at the age of 20.

Upon his return, he married his fiancee and decided to open his own workshop. He reached an agreement with someone who was closing their shop, leading him to start his own business in a 15 m² workshop in 1968, before departing for Germany as a laborer.

I MAKE PLOUGHS!

SINCE 1968, WITH A PASSION FOR ABUNDANCE…

Initially focusing on welding, Nihat Koç mainly repaired broken agricultural machinery. One day, a farmer whose machine he had repaired admired its performance and inquired about his primary trade. When Nihat Koç replied, “I make ploughs,” the farmer requested a plough from him. After completing this first plough, local acquaintances and neighbors began placing orders.

Nihat Koç started producing one “two furrows” conventional plough per week, marking them with the name “KISMET.” As his ploughs gained popularity and he received more orders from neighboring regions, Nihat Koç fully committed to plough manufacturing.

First Export

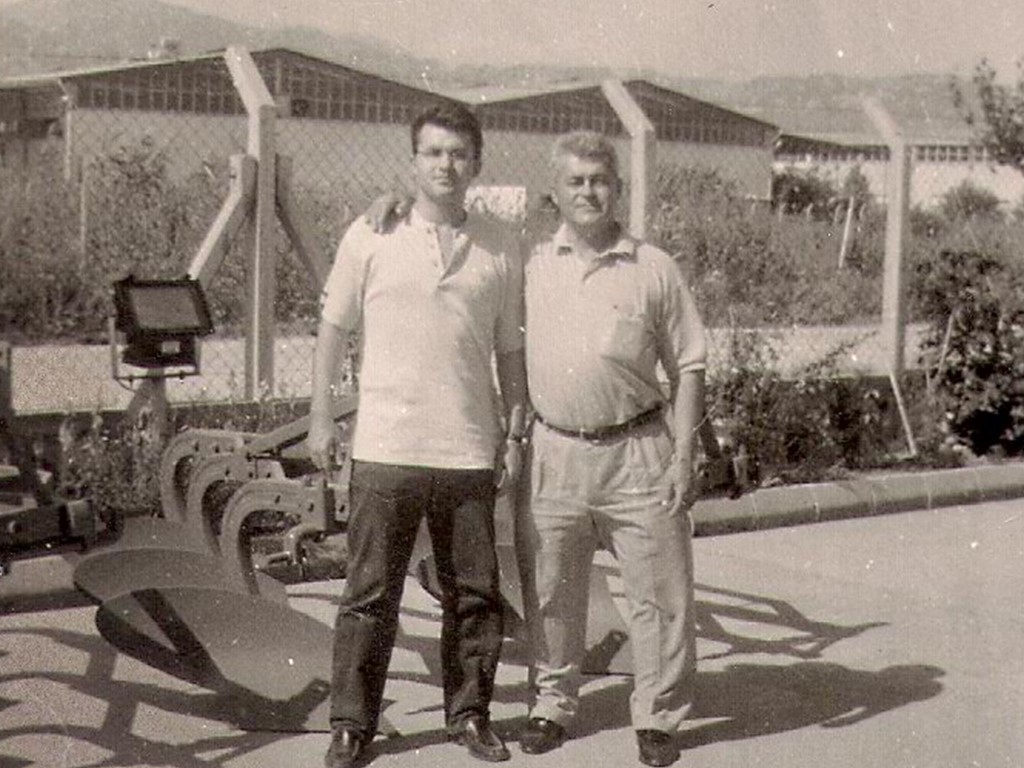

In 1974, his son Bülent Koç was born. By 1976, the original workshop had become insufficient, prompting the rental of a larger 50 m² shop. New equipment, including a press and cutting tools, was acquired, and Nihat Koç began cutting materials in-house and shaping ploughs, eventually starting the production of “three furrows ploughs.

In 1983, the workshop outgrew its space again, leading to the relocation to a 400 m² facility. This new workshop, staffed with 20 workers, marked the beginning of “four furrows” plough production. The workshop continued to expand and improve, and in 1989, Aydın Pulluk received its first export order of 180 ploughs from Syria. In 1991, the company moved to a new 4000 m² factory in the Astim Organized Industrial Zone, where it began producing “five furrows” ploughs.

SECOND GENERATION TAKES OVER.

The 1990s marked the era when the second generation took over at Aydın Pulluk. Bülent Koç, born in 1974 in Arapkuyusu Village, Aydın, completed his high school education at Aydın High School before enrolling in the Agricultural Engineering program at Gaziosmanpaşa University. Bülent Koç began working at the factory in 1995, even before his graduation in 1997, as his father gradually started to step back from daily operations.

Bülent shared, “I worked in every department when I first started. They placed me wherever there was a need. I learned a lot about machinery and welding. My father’s goal was not just to train a craftsman but to instill a passion for the work and enhance my theoretical knowledge. I believe loving what you do is essential for continued success. Personally, I have a deep affection for ploughs.”

NİHAT KOÇ’S PASSING

Nihat Koç, the founder of Aydın Pulluk, fell ill in 1997 and passed away in 1999. Bülent Koç fondly remembers his father, noting, “My father had no inheritance from his parents; he started a business from scratch and never wanted to return to his roots. He valued success greatly and was a typical Anatolian man with an open mind. He allowed me to explore different ideas in the business and supported my growth. He was a master craftsman who took pride in his work. Even though I leave some tasks to the experts now, my father was deeply involved in every aspect of the business until the age of 40, at which point he focused on training others.”

GROWTH THROUGH FAIRS AND EXPORTS

The 2000s marked Aydın Pulluk’s active participation in both domestic and international trade fairs. Bülent Koç observed significant developments in exports following these fairs. He noted, “Participating in domestic fairs allowed us to better understand the needs of farmers and the market. International fairs provided insights into our competitors and the standards in Europe. We realized that our ploughs were not suitable for European markets at the time due to our design focus on Arab requirements. However, we quickly adapted and began closing the gap, leading to accelerated growth. We now closely follow global trends and are competitive with major producers.”

"MY MAIN GOAL IS TO PRESERVE THIS LEGACY"

Bülent Koç emphasizes the company’s dedication to plough manufacturing alone. He states, “We have never ventured into supplementary soil cultivation tools, nor do we plan to. My main goal is to maintain this legacy. Companies like ours, after reaching a certain point, focus on honoring the founder’s name rather than just earning money. The aim for second and third generations is to achieve success and continue this legacy. My children work with me during the summer, and I plan for them to love this work, although this cannot be guaranteed.”

“WHAT HAPPENS IN EUROPE ALSO HAPPENS IN TURKEY”

Bülent Koç highlights that economic fluctuations in Europe are reflected in the Turkish market. He explains, “In this sector, trends in Europe are mirrored in Turkey. Although there are fewer farmers worldwide, the number in Turkey is still high but decreasing due to professionalization and mechanization. Even if some say that new products may not sell immediately, I believe they will be needed eventually. We are currently producing all types of ploughs globally and are investing in improving their design. We have completed the construction of our new 40,000 m² factory and plan to use the existing site for spare parts manufacturing. We are focused on refining our products and enhancing our production capabilities.” Today, Aydın Pulluk exports 40% of its production, serving approximately 20-25 countries, particularly in the Balkans. The company is poised for further growth and innovation in the coming years.